PalmSHIELD Products are Engineered

Wind Load Requirements

Today’s architectural community is now giving consideration beyond the building to meeting wind load requirements. Architects and engineers are viewing the entire site and site amenities for compliance with the American Society of Civil Engineers wind load requirements. Safety is our highest priority. Safety must also include assuring non-habitable structures are secure and not posing a safety risk to habitants during these wind events.

Once designers have met all obligations to providing safe structures; these planners are now giving consideration to assuring all site amenities outside the building are designed to mitigate any preventable damage, causing considerable construction expense to property owners and unsightly outcomes for tenants.

Exposure Category

What does “Exposure category mean? An exposure category (B, C, or D) is a condition that reflects the characteristics of ground surface conditions for a site where a structure is located. Exposure category is used in calculating the specified wind pressures for a structure or building with exposure B yielding the lowest wind pressures and exposure D yielding the highest wind pressures.

- Exposure B applies to urban and suburban areas, wooded areas or other terrain with numerous closely spaced obstructions having the size of single-family dwellings or larger. Exposure B is associated with site locations in a residential subdivision. Most site locations are concluded to be Exposure B unless the site meets the definition of another type of exposure.

- Exposure C applies to open terrain with scattered obstructions with heights less than 30 feet extending more than 1,500 feet from the building site. Exposure C includes flat open country, grasslands, and shorelines in hurricane-prone regions.

- Exposure D applies to flat, unobstructed areas open to wind flowing over open water (excluding shorelines in hurricane-prone regions) for a distance of one mile or more. Exposure D includes shorelines in inland waterways, the Great Lakes, coastal areas of California, Oregon, Washington, and Alaska. Exposure D from the shoreline a distance of 1,500 feet or 10 times the height of the building or structure. Whichever condition is greater.

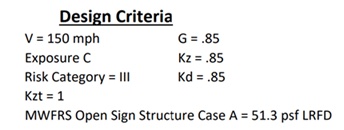

PalmSHIELD recognizes the need for architectural screen fencing and wall to be engineered to meet the specific ASCE standards. Our engineering group not only provide a full line of products engineered to meet the basic 120 mph ASCE standard but product designs to meet the more stringent 150 mph standards. Our designers have teamed with licensed structural engineers to set design parameters for material selection and design to provide screening options that comply with below design criteria.

If you determine your site resides within this zone and meets these exposure and risk category criteria, please communicate these requirements to our estimating and design team. They will work together to assure they provide you with the selected screening in compliance with the required ASCE wind load requirement. Please note that all wind load compliant products will state the respective compliance on any system proposals and design drawings. If you do not see your required wind load requirements on these documents your screening system may not be compliant.

PalmSHIELD offers our basic engineering for both our 120 mph and 150 mph compliant designs. If you require site specific engineered drawings stamped by an engineer licensed within your jurisdiction, please notify PalmSHIELD and we will team with local engineers within your area to provide these drawings. Engineered stamped drawings are not included in our proposals unless specifically requested and stated. These engineered drawings are only provided upon request and acknowledged by PalmSHIELD.

Most PalmSHIELD systems are designed to meet 120 mph rating. Please request 150 mph rating at time of quotation. PalmSHIELD does not guarantee wind load rating unless specifically requested and stated by PalmSHIELD per our quotation and fabrication documents

Structurally Sound

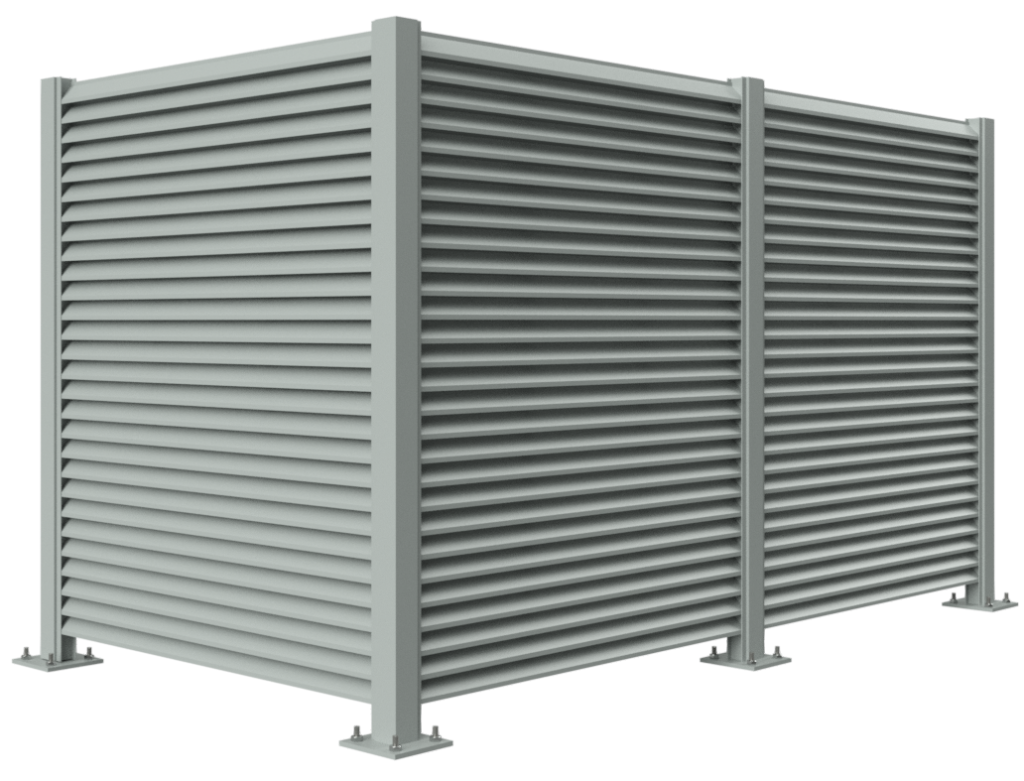

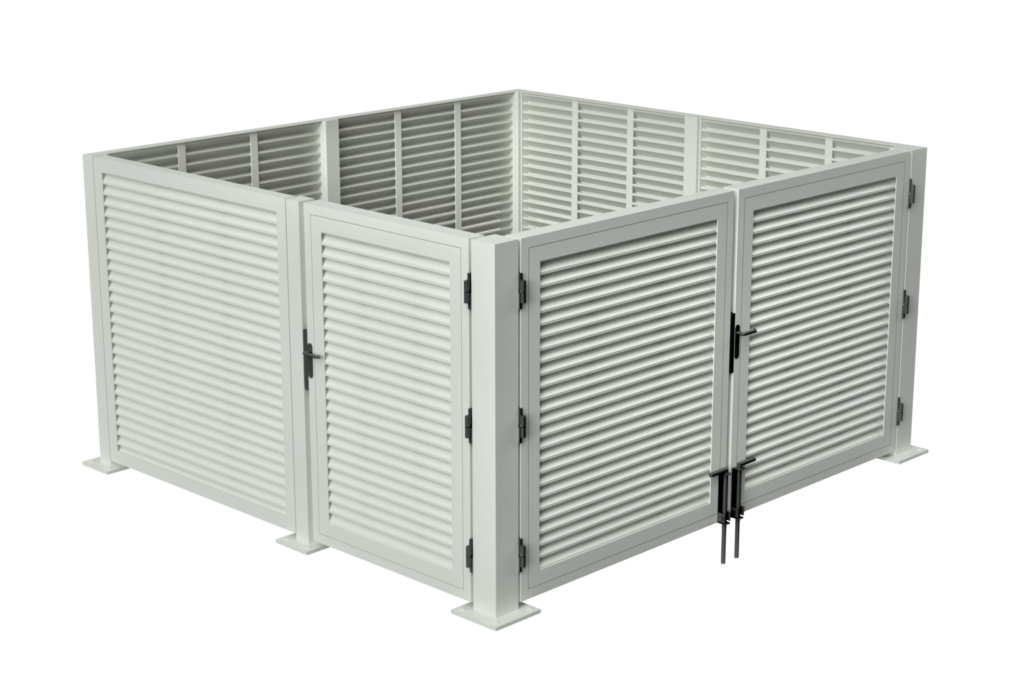

PalmSHIELD has been working with engineers for over twenty years in assuring that our architectural screen fencing and wall, louvered mechanical equipment screen and rooftop screen fencing are structurally sound and do not interfere with the mechanical performance of the equipment they were intended to screen. Mechanical equipment may include compressors, condensers, chillers, rooftops, HVAC, compactors, breakers, meters, containers, generators, and like-kind equipment. Each one of these unique pieces of equipment has recruitments specific to the volume of air surrounding the equipment and the exchanging of that air which allows for dispersing heat.

Meeting The Standards

PalmSHIELD mechanical equipment screen and architectural screen fencing and wall has been engineered to meet the standard in openness for maximum air flow while still maintaining 100% direct visual screening. The percentage of openness is the actual openness between the louvers over a specific area. The smallest opening between two louvers is the greatest factor impacting the percentage of openness. PalmSHIELD’s louvered systems typically have the louver opening based on 100% direct visual screening is 2 ¼” In other words, with 4” tall louvers spaced 3 ½” on center, the smallest opening is 2 ¼”. Boiled down, every 3 ½” of travel, there is a 2 ¼” opening. This ultimately translates into approximately a 64% free area. All PalmSHIELD systems incorporate our proven fully framed panels, engineered plated posts, our Gorilla hinges and the Locinox re-keyable lock system with an auto latch bolt and stout hook latch.

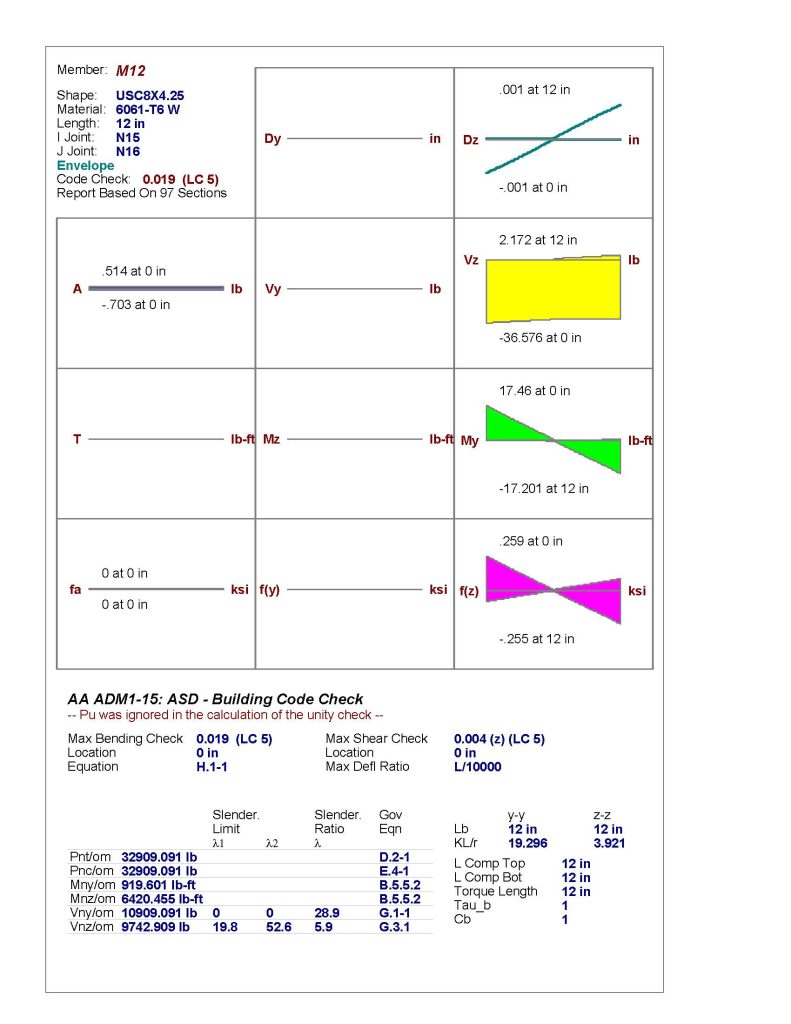

Engineering

Any architectural screen or louvered fence will increase the wind load on its supporting structure. This has traditionally been an educated guess with a considerable safety factor. However, most architectural and louvered equipment screens are attached to adjoining walls and buildings that must meet an even greater wind load coefficient for solid surfaces.

Though PalmSHIELD’s louvered systems may be installed as a wall louver where the louvered panels are installed like windows and attached to the building structure, PalmSHIELD’s louvered systems have their own independent structures that classify them as standalone louvered equipment fencing or screen systems. It’s this independent structure that carries the load of assuring the overall system meets the latest IBC and UBC codes.

Precision & Design

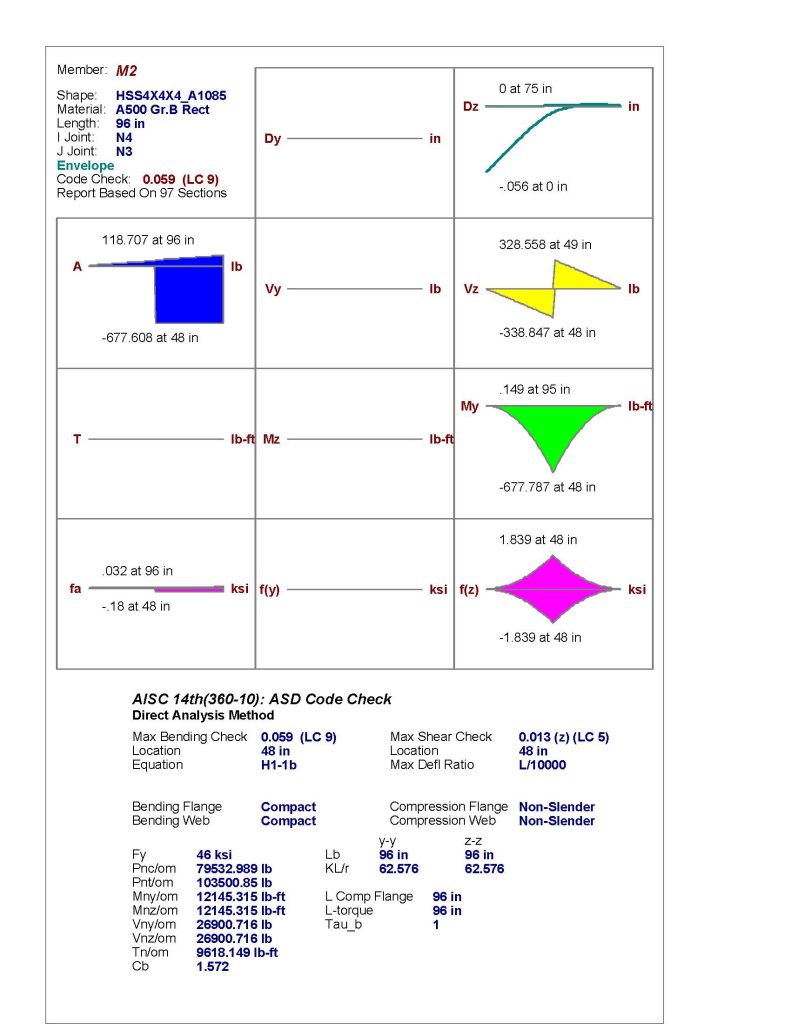

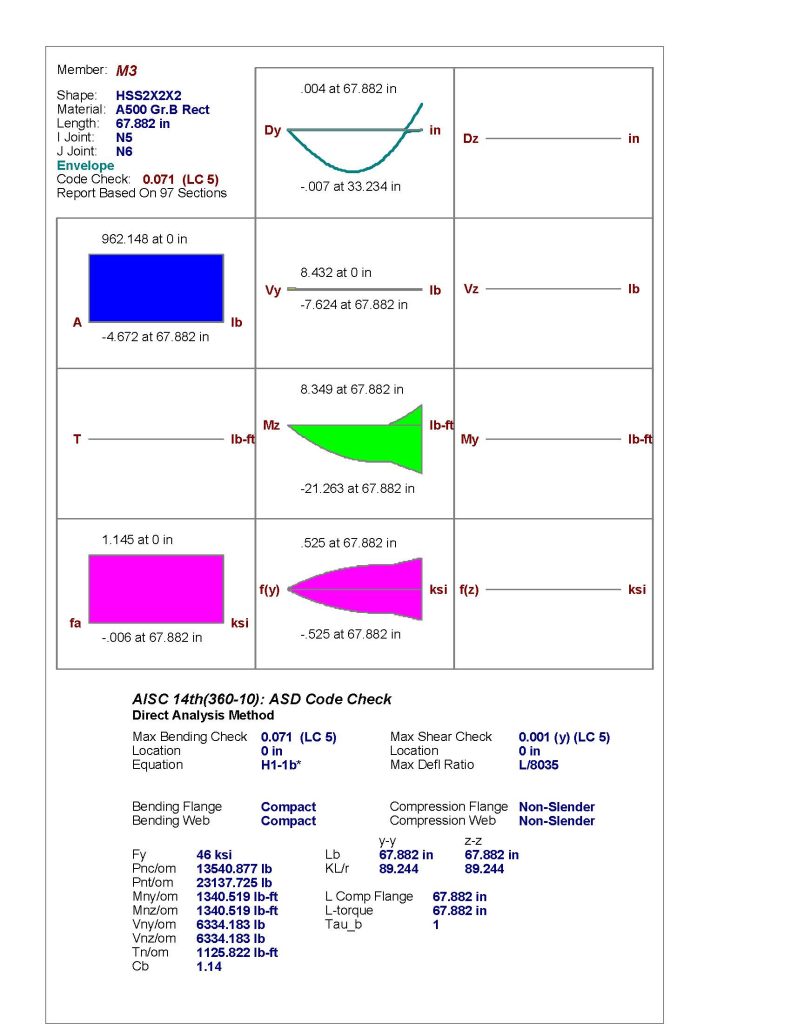

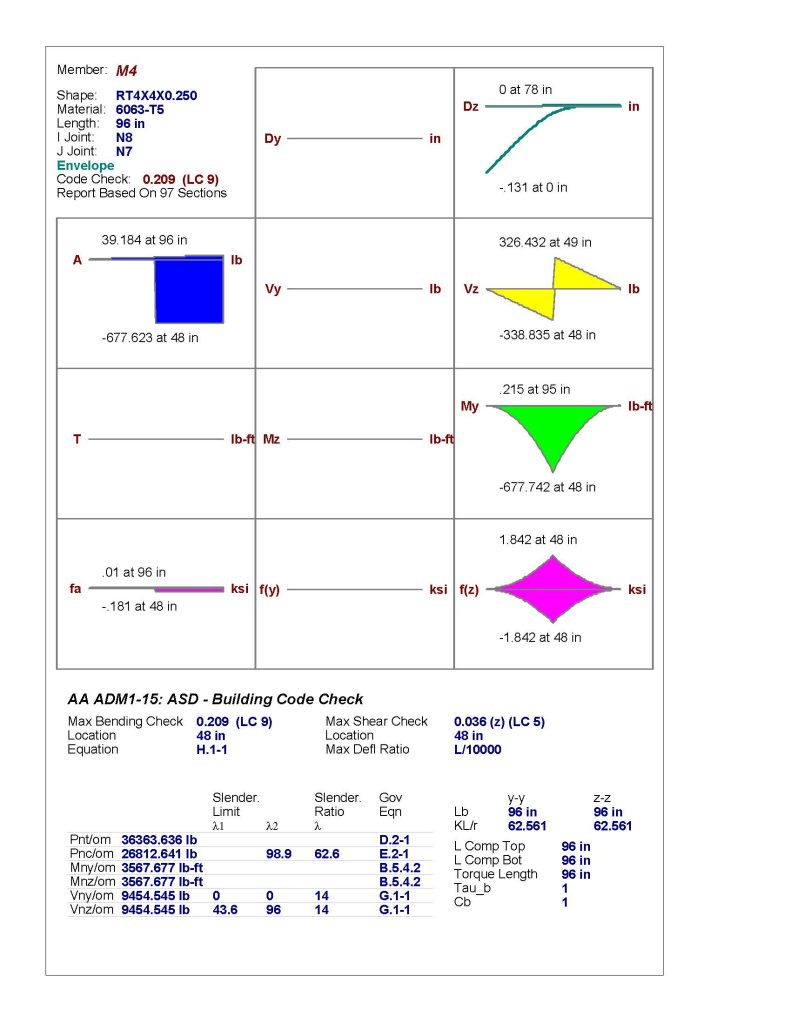

PalmSHIELD’s screening, louvered and rooftop products have been designed and engineered to meet these codes. Through measured calculations, PalmSHIELD’s louvered panels with an 80% opening have a horizontal load of 22 psf. This wind load calculation is based on 90 mph winds which complies with the 30 psf load requirement on solid building surfaces. These results are based on a risk factor of I, an importance factor of .87, a 8′ height and post spacing at 8′ on center.

These load calculations are used in selecting the design of all of our mechanical equipment screening. From these calculation, we can determine post design, material selection and post spacing. By applying the load per square footage of the panel size, we can properly estimate these specifications on a per case basis. It must be stated that these are only estimated loads because loading will vary exponentially based on the height of the panels. Not all wind loading is equal top to bottom of the screening panel. For actual engineered calculations, each system must be independently engineered by a registered engineer within the jurisdiction it will be installed. This level of engineering is not included in the standard PalmSHIELD quote. If local stamped engineering is required for your system, please indicate so at time of quote. We will contact a local engineer in the respective jurisdiction and work directly with them to provide the necessary calculations.

Anchoring

Mounting Options

It is up to the owner or project engineer to select the type of anchoring system for anchoring PalmSHIELD’s plated column design to your structure. We have worked with engineers across the United States to attach the PalmSHIELD architectural screen fencing and wall product to structural steel and adjoining structures for rooftop installations. However, the majority of our installations are mounted to the top of concrete surfaces.

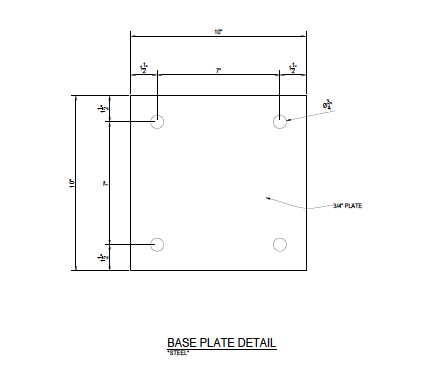

Base Plate Details

PalmSHIELD uses a very wide ¾” base plate design that is gusseted to the posts and welded in accordance with AWS D1.2 requirements and related certification. This large plate design is intentional to allow the customer to use a wide variety of anchoring options. The use of this large plate spaces the anchor holes more than 7 inches apart. By spacing the anchors this distance, it prevents overlapping of the tension placed on the concrete by each anchor.

Anchor Engineering Considerations

When installed, concrete anchors place tension against the adjoining concrete under a load. The tension begins to diminish the farther away you get from the center of the anchor. Assuming you have adequate concrete of at least 4000 psi, the load can be predicted by the anchor manufacture relative to the area of concrete impacted by this tension. If concrete anchors are installed too close to one another, this loading is overlapped and increased exponentially thus potentially causing the concrete to fail or sprawl. Consideration should also be given to how far the anchor is installed relative to the edge of the concrete. If there is not enough concrete from the center of the anchor to the edge of the concrete to absorb the tension of the anchor under a load, the concrete may fail. Anchor manufactures call this area around an anchor a sprawl cone with the larger end of the cone closer to the top of the anchor. When two anchors overlap or the cone reaches to the edge of the concrete, there is concern that the anchor may fail.

PalmSHIELD is not recommending any anchor, anchor spacing, depth or edge spacing. We are simply offering some solid advise to our customers that these are important considerations that should be properly engineered. If notified at time of quote request and provided with the site specific engineering requirements, PalmSHIELD can provide you with engineering that will determine your specific anchoring requirements during the submittal process. On a site specific basis, PalmSHIELD can offer jurisdiction specific engineering working with engineers who are certified in that jurisdiction. As our PalmSHIELD product has been stamped for approval in multiple installations, we work seamlessly with engineers to meet your requirements.

Rooftop Screen Rail Structural Calculation

PalmSHIELD’s A1000 Equipment Rail is designed giving consideration to meeting structural performance, a wide variety of roof tops, easily sealed to prevent roof leaks and custom patterns for attachment.

- The primary trapezoidal rail is constructed of 8” x 2” x ¼” structural aluminum channel. Being purposeful in choosing this profile, PalmSHIELD wanted to be sure we selected a large enough profile to meet almost any screen height and wind load requirement. This wide profile was also selected for its ability to customize the pattern for attachment to a wide variety of roof types. Metal standing seam roofs require roof rails to be attached to underlying roof beam, purlins and bar joists. The location of these structural members do not always line-up with rooftop screening rails so PalmSHIELD uses this wide continuous profile for the end user to custom design where the anchoring will occur to capture the roof structural members.

- Each roof rail is custom designed to meet roof slopes and changes in elevation. End users and designers provide PalmSHIELD with roof slopes and changes in roof elevations and PalmSHIELD provides detailed fabrication drawings showing each roof rail with its unique slope and elevation. PalmSHIELD recognizes that not all roofs are the same and customization is necessary without compromising structural requirements.

- Roof rail lengths are customizable to meet roof structural members and improved structural performance. Each rail includes a 45 degree brace that extends from the base of the rail to the equipment screening column. This bracing significantly improves performance and reliability.

- All roof rails are designed to work with PalmSHIELD screening plated columns. The top of the roof rail will marry-up with the column hole pattern, making attaching columns easy and performed mechanically in the field. All points of attachment are easily accessible and no disassembly of the rail is required.

- Roof rails lower rail sits flush on top of the roof. It accommodates U-bolt, epoxy anchor or mechanical anchor attachment to the roof. With a considerable surface area, the rail will not damage TPO, EPDM, PVC, Asphalt and coated roofs. Sealant may be placed under the lower rail, around anchors and along the entire edge of the rail.

PalmSHIELD’s A1000 Equipment Rail is engineered for 120 mph wind speeds at eight foot tall and rails on five foot centers assuming the screening is solid. This is the basis of our engineering. If additional site conditions are warranted beyond these conditions, PalmSHIELD will work with our engineers and local site engineers to meet these conditions. We are subject matter experts and understand how to design our equipment rails to meet these conditions.

Not Just Another Architectural Screen, Mechanical Equipment, Louvered Screen System Manufacturer.

We Design Each System With The Customer In Mind.